Product added to cart

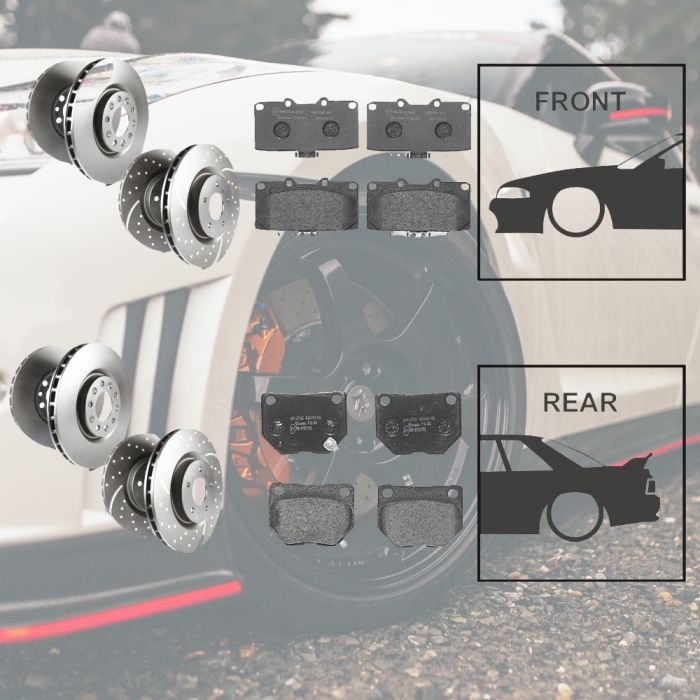

Front & Rear Brake Pads & Discs For Nissan R35 GTR VR38DETT

From £242.51 £202.09

To £4,983.54 £4,152.94

Lead Time: Make Selection For Availability

SKU

NISSBPDK11

Fast Shipping

Hassle Free Returns

Brake Pads for Nissan R35 GTR

Hawk HPS

HPS - High Performance Street disc brake pads are world renowned for increasing stopping power on your street legal vehicle. Increasing the performance of your vehicles braking system is easy when you choose Hawk Performance’s HPS braking compound. This unique Ferro-Carbon formula was developed for street performance using the safety and quality of Aerospace and Motorsports severe-duty friction technology.

The High Performance Street compound offers a higher coefficient of friction over stock brake pads and can provide you 20-40% more stopping power and higher resistance to brake fade than most standard replacement pads. Less fade means you will have a highly durable brake pad with less brake dust.

All Hawk Performance High Performance Street brake pads provide a limited lifetime warranty, ensuring products to be free of defects from manufacturer’s workmanship and materials

Ferodo DS2500

The DS2500 material has a friction level of approximatively 0.50 which remains constant at any speed and at any temperature that the brake system is working at. The DS2500 compound is designed for racing applications thanks to its excellent speed and temperature sensitivity characteristics but it can also be used for fast road use

The main characteristics of DS2500 are:

-Race developed

-Performs equally well on heavy and light cars

-20% less pad wear than competitive products.

-Minimal bedding-in. Supplied ready to use.

-Disc friendly.

-Consistent friction level with changing temperatures and speeds to give optimal pedal modulation.

-High friction level at low temperature (good cold braking).

-High friction level at very high temperatures.

-35% less compressability than competitive products (racing pedal feel).

-Less noise for increased driving comfort

Discs for Nissan R35 GTR

*Please note all discs are sold as a pair or single rotors if sided.

Designed for extreme road and race applications.

DBA 5000 T3 slot design ‘sports’ the same benefits as the 4000 SERIES except for one major structural advancement. The 5000 SERIES brake rotors incorporate Alumalite hats made from 6061-T6 Aeronautical grade aluminium. The Alumalite hat reduces unsprung weight for improved suspension and handling performance as well as allowing uniform expansion of the disc rotor during high performance use. The Alumalite’s ability to reduce the level of heat transfer adds to the longevity of both the disc rotor and other vehicle components such as brake pads and wheel hub bearings.

The tri-symmetrical slots also increase the number of out-gassing exit points for brake pad friction gases to escape through, further increasing the consistency and effectiveness of every brake stop.

Description

Advantage

Benefit

"T3 Slot 48 precision CNC machined slots"

Tri-Symmetrical curve slots dampens the vibration harmonics or noise

A quieter, responsive and smoother brake pedal feel

Increased number of out-gassing exit points for brake pad friction gasses to escape through

Increases the consistency and effectiveness of every brake stop

Universal slot design

Eliminates the need for left and right discs

Kangaroo Paw – 144 diamond and tear drop pillar ventilation system

Increased surface area resulting in greater heat dissipation

Minimises brake fade and increases braking effectiveness

Increased surface area resulting in greater heat dissipation

Prolongs service life for both pads and rotors. Reduces mechanical damage and associated costs

XG150 High Carbon Alloyed Iron

An increase in thermal capacity property allows the rotor to handle constant extremes of heat over extended periods of time

Minimises warping and cracking and prolongs the service life of the rotor

Special formulation designed to respond to DBA’s TSP process

Minimises warping and cracking and prolongs the service life of the rotor

Thermographic Temperature Monitoring

Heat paint markings change colour at specific temperature thresholds

Offers the driver a clear indication of peak braking temperatures

When temperature thresholds are exceeded paint markings will permanently change colours

Allows the driver to monitor rotor fatigue and decide on rotor replacement and to assist resellers with warranty claims

Paint protection on non-friction areas

Reduces corrosion

Stops any unsightly rust formation

Enhances appearance

Adds value to the product

Home grown inspiration

Inspired within Australia’s heartland, DBA developed the Kangaroo Paw cooling system. This patented ventilation system provides a much more efficient method of keeping the rotors cool under the heaviest of braking applications.

Dimensionally precise

Friction surface is CBN (Cubic Boron Nitride) machine turned for improved DTV (Disc Thickness variation) and parallelism. This provides a more dimensionally precise and stable surface finish when compared to ‘ground’ finished disc rotors.

Thermo-graphic Temperature Monitoring

4000 and 5000 Series rotors also incorporate DBA’s Thermo-Graphic heat paint markings which change colour when specific temperature thresholds are achieved. By monitoring the markings, drivers can check their braking performance quickly and easily.

High Carbon Alloyed Iron

Through extensive testing and feedback from performance drivers worldwide, DBA has developed a unique cast iron formula (XG-150) for use in all of it’s CLUBSPEC disc brake rotors. The XG-150 formula, with it’s increased thermal capacity properties, is designed to respond to the DBA TSP process allowing the rotor to handle constant extremes of heat over an extended period of time.

Thermal Stability Profiling (TSP)

TSPTM is a process of relieving the stresses that are naturally generated in the casting and manufacturing processes. This process stabilises the stresses by re-aligning the microstructure of the iron, resulting in a disc rotor ideal for heavy road braking and race applications.

.

| Part Type | Brake Kit |

|---|---|

| Lead Time | Make Selection For Availability |

| Vehicle / Engine Manufacturer | Nissan |